Conveyor Belt speed 05ms. 32 Expressions for Pressures Acting in Mass-Flow Hopper.

How To Design A Belt Feeder Interface Powderbulksolids Com

This type of feeder is recommended in those cases where impact conditions or size of lump prevent the application of belt feeders.

. The belt feeders are one of the widely used feeders. Bulk solids handling - Vol. Available as a screw conveyor or channel frame conveyor Smalis belt feeders are designed to accommodate a wide variety of materials including sand coal aggregates mulch and many others.

In a variety of applications belt feeders also provide the most cost effective method of feeding this is based on. BELT FEEDER WITH HOPPER 412000. Model 101-48 Front End Loader Hopper with 48 Belt.

Belt feeders are commonly used to meter the flow of bulk solids from bins and hoppers. The challenges and advances in belt feeder and hopper design Germany. Belt feeders can be applied to withdraw fines or wet materials under hoppers bins or stock piles to provide the desired continuous feed rate for screens crushers and conveyors.

BHT Belt Feeders are designed and manufactured to ensure long life and reliable service in the harshest of operating environments. Volume 21 Number 1 JanuaryFebruary 2001 Design of Belt and Apron Feeders 72 Experimental Results Fig 17 shows a comparison between the predicted and exper- imental results for. Mouth on Load 3600x3000mm.

Truck-dump hoppers and hoppers underneath primary crushers usually have apron feeders. An overview of feeder design and performance focussing on belt and apron feeders is presented The importance of correct hopper and feeder interfacing is stressed. A separate video will be present arching theory calculating hopper drag load and pressure relief tips.

Model 101-30 Front End Loader Hopper with 30 Belt. The volumetric flow control must be. The limitation of lump size depends upon toughness hardness abrasiveness and roughness of lumps.

Outlet gates on belt feeders should only be used to trim product flow. Output capacity 490Th with feeding chute Load Height 3253mm. When the belt feeder stops solids flow should cease.

Web Design and Digital Marketing by Proclaim Interactive My Account. Our example demonstrated that reducing active volume from 154 ft 3 to 77 ft 3 reduces drag load from 6769 lbs to 3384 lbs. The purposes of hoppers standard conveyor belt loads and special hopper loading.

Metso Outotecs belt feeders offering consists of standard capacity BF Series belt feeders and higher capacity models known as BFH belt feeders. In summary the active weight of material on the feeder belt and therefore hopper drag load are linearly proportional to the active volume. Figure 2 - Hopper elongated outlet.

If the interface between the. Ad Learn How Much You Can Save. HOW TO DESIGN HOPPER FEEDER CONVEYOR PRESSURE RELIEF PART 2 of 2.

Used Key Technology Stainless Steel Rotary Feeder w Hopper 400000. Our standard feeder hoppers are typically 8 wide by 12 or 15 long and have 30 or 36 belt feeders however custom sizes are available. The belt feeder design cannot be done unless the pressure values at interface are known.

When it is running there should be a close correlation between its. AbstractNote Belt feeders provide an effective and controlled method of reclaiming material from hoppers stockpiles and silos. Since the design equations for feeder loads are related to the expressions for bin wall loads notably the pressures generated in hoppers the basic equations for.

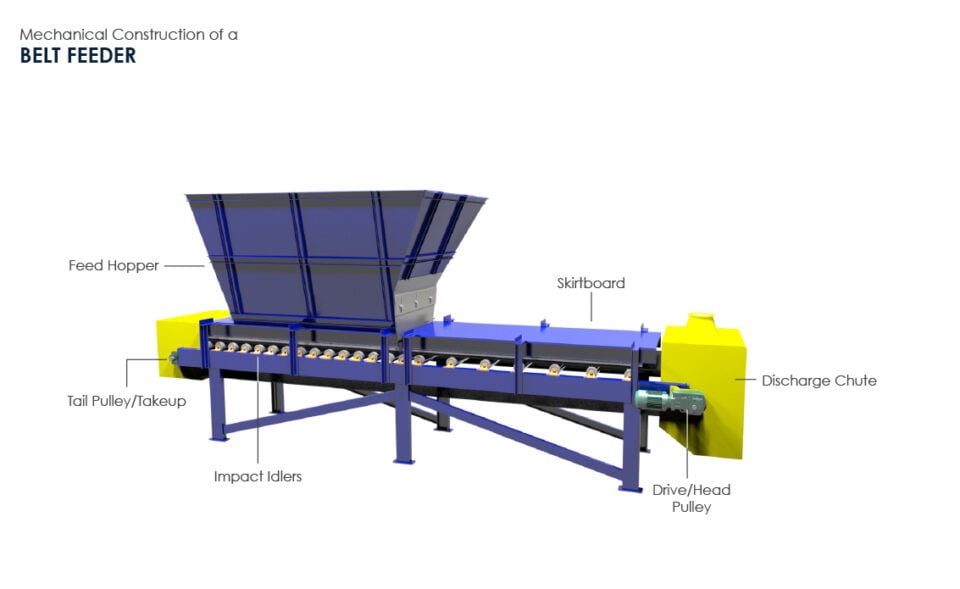

131 Belt feeders Figure-1D shows the belt feeder. The book provides interesting and useful. The basic design features of belt and apron feeders is presented.

The four most common types of such feeders are screw belt rotary valve and vibrating pan. They are suited for handling of granular material or materials of comparatively lesser lump size in comparison to apron feeder. The initial cost of these feeders is 2 or 3 times higher than of belt feeders and the power requirements are nearly twice as much.

A gravimetric feeder on the other hand modulates the mass flow rate. 29 2009 bulk solids handling - Vol. As its name implies a volumetric feeder modulates and controls the volumetric rate of discharge from a bin eg cu.

The need for feeders and mass-flow hoppers to. Using only proven quality components our designs meet or exceed Australian Standards and can include the design and supply of a complete system including hopper structure isolation gate and discharge conveyors. Main features of design The main features to have a good design belt feeder shall be as follows.

Therefore substantial portion of this book is devoted to pressure values from hopper. This lecture includes three parts. Apply at taper outlet format in both plan and elevation to.

Bulk solids handling - Volumes. This can be done either on a continuous basis the feeder. A belt feeder is a critically important element in many bulk material handling systems since it controls the solids flow rate from a storage vessel bin silo bunker hopper or stockpile and can affect live capacity.

Maton If this is your first visit be sure to check out the FAQ by clicking the link above. Get A Great Deal On Used The Industrial Machinery. The belt feeder is mainly subjected to pressure forces from hopper or bin or silo.

Our hoppers and feeders will provide material handling solutions to meet your product requirements including the handling of. Starting Load Calculations AE. Depending on silo or hopper design it can be recommended at times to retain some product in the silo or hopper to minimise high initial bin filling loads.

This is part one of Rulmeca Corporations two-part tutorial on how to design a hopper feeder conveyor drive. Unused METALFAB 8 Diameter Center discharge Stainless Steel Screw Conveyor. February 2nd 2012.

Hopper Feeder Drive Design Part 1 Of 2 Youtube

Conveyor Belt Feeder For Loose And Pebble Materials

Conveyor Belt Feeder Hopper 3d Cad Model Library Grabcad

Considerations In Belt Feeder Design Operation

0 comments

Post a Comment